TECHNOLOGY

Discover the technology and potential of the VMS division.

-

TECHNOLOGY

-

R&D CAPABILITY

R&D CAPABILITY

Have a glimpse of our research and development capabilities and scope.

-

Application Engineering

-

VMS COMPONENT

-

VMS SYSTEM

-

-

Advanced Engineering

-

MATERIAL

-

PRODUCT

-

-

Verification & Validation

-

CAE

-

Measurement & Test

-

Correlation

-

-

Application Engineering

MATERIAL & PRODUCTDTRamid®, Active Mount & Switchable Mount, Durabush®, Plastic Sub-frame Bushes are

VMS all examples from DN’s long history of innovation and being first to market with new technologies. VMS DN is actively engaged in the challenges created by future electric powertrain technologies and supporting our customers to optimise their vehicles. -

Advanced Engineering

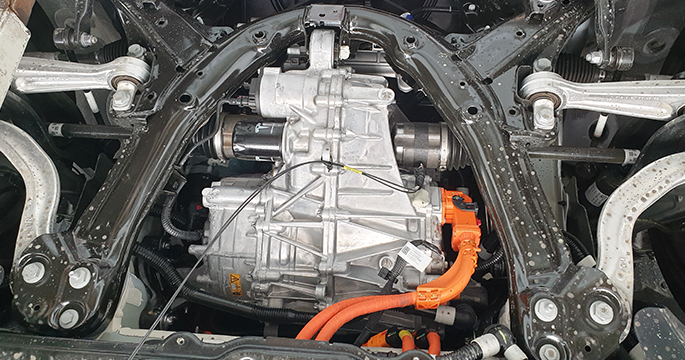

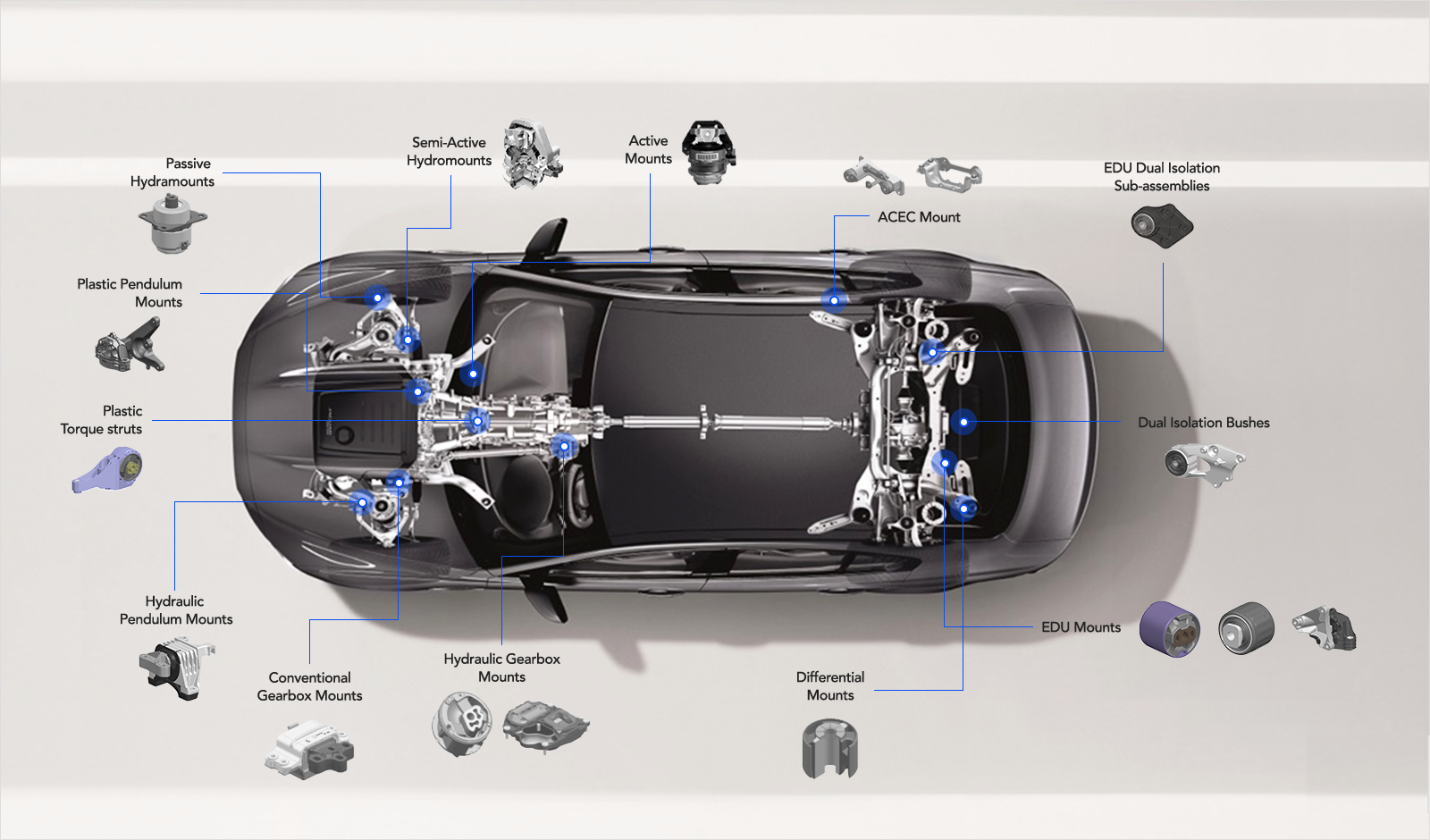

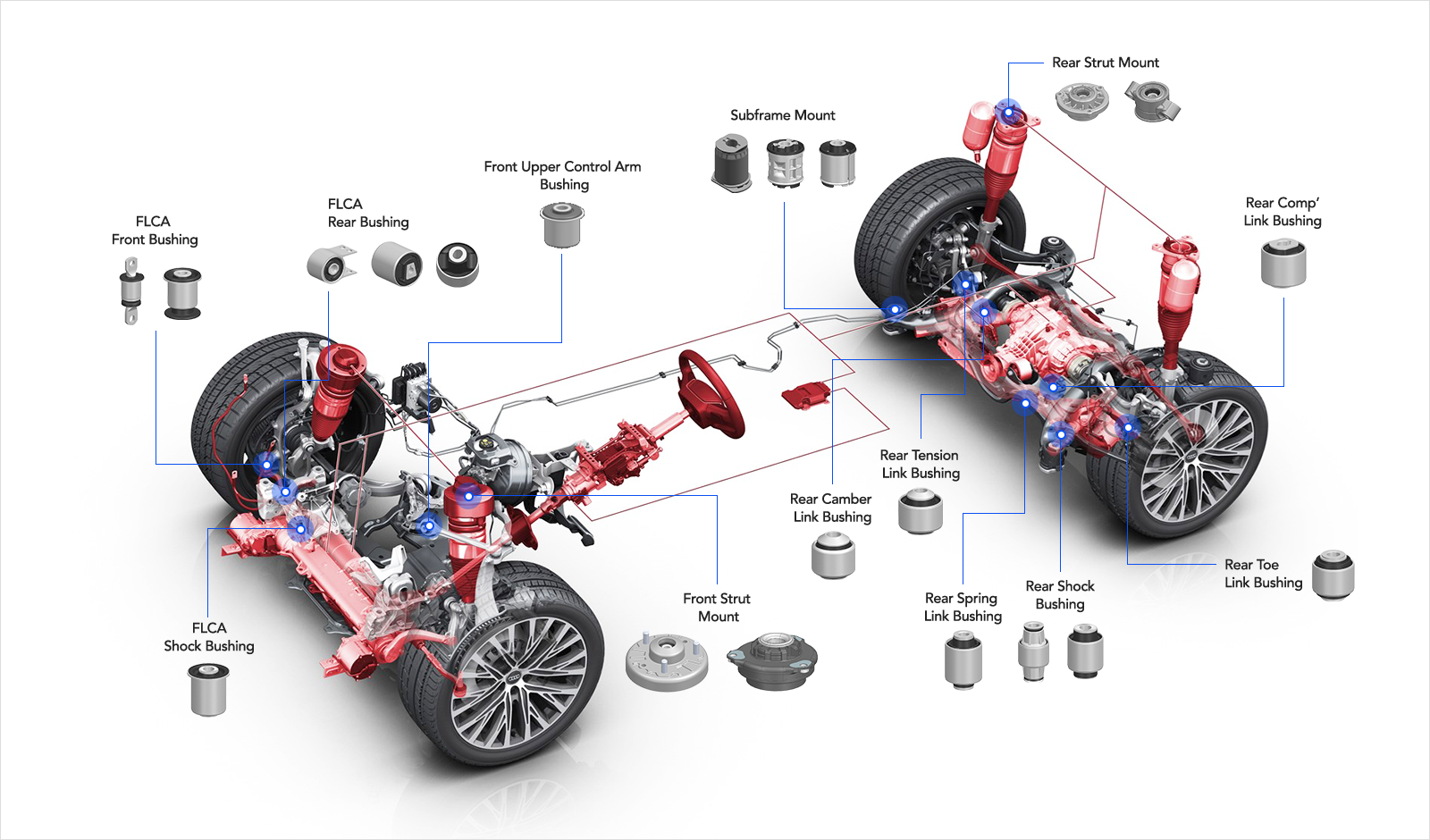

VMS COMPONENTDN provides a broad product portfolio, which covers vibration management applications in passenger cars, commercial vehicles and railways.

-

VMS SYSTEM

Full system development and validation are the key to understanding

the problems and solutions needed for modern powertrain,

chassis and suspension systems.

DN works closely with many OEMs at the system level,

helping to define effective solutions for the future.

-

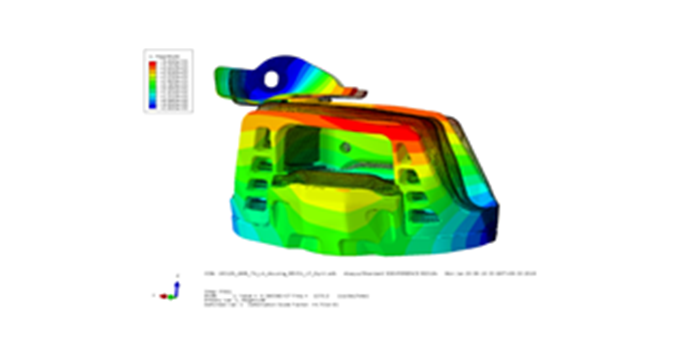

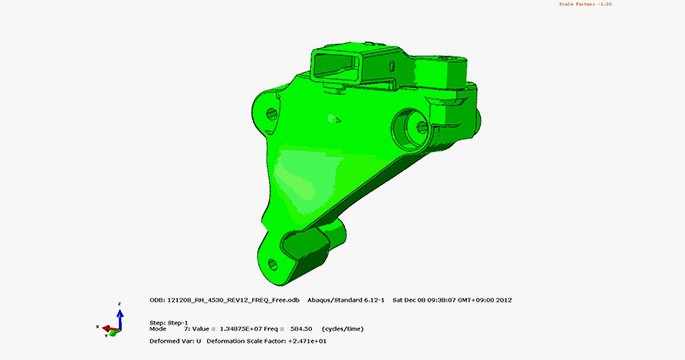

Verification & Validation

CAEDN is fully equipped with a range of CAE techniques to enable us to virtually validate new designs,

from a single component through to full system analysis.

By continuing to heavily invest in this area and through

continuously advancing simulation techniques and capabilities, we are able to

progress our “right first time” design philosophy leading to reduced development times and satisfied customers. -

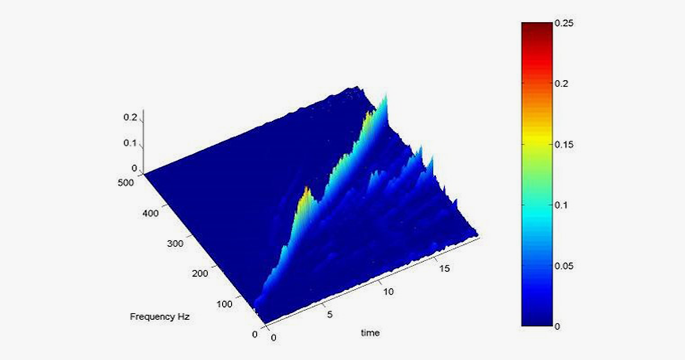

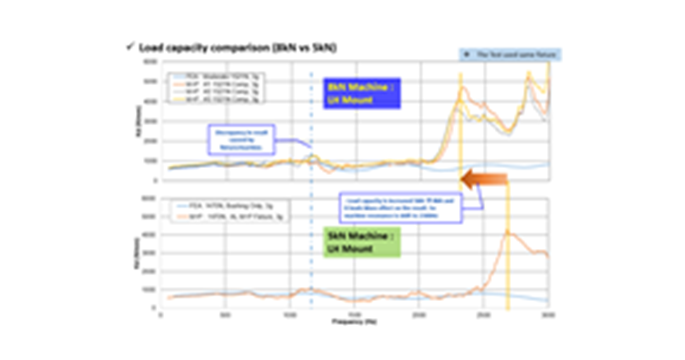

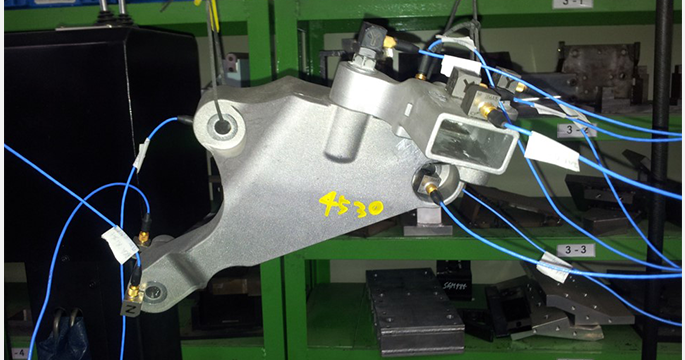

MEASUREMENT & TEST

DN has a full range of specialised facilities and trained engineers to measure,

test and validate our products and processes. These facilities and capabilities are invaluable

when it comes to verifying new technologies and benchmarking products from the field.

Each Tech Centre has its own test laboratory, but by standardising on

equipment and techniques we are able to support each other ensuring effective utilization of our R&D resources. -

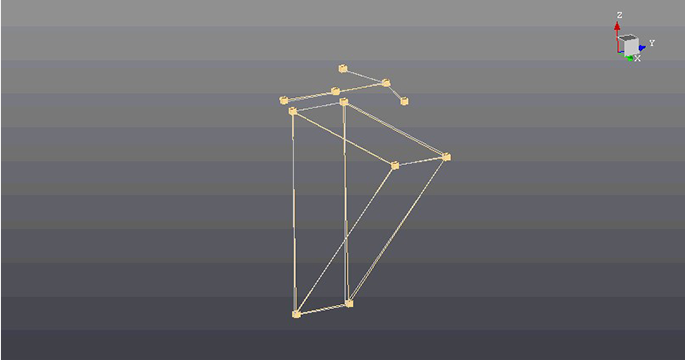

CORRELATION

By continually reviewing the correlation between CAE and actual measured

performance of both products and materials,

we are able to ensure the continuous improvement of our CAE techniques.