PRODUCTS

Introducing the best VMS division products by sector.

-

PRODUCTS

-

QUALITY & PRODUCTION

-

PRODUCTION PROCESS

PRODUCTION PROCESS

This is to inform you of the product production process of DN.

To realize this belief, our operators are provided with trainings for all the knowledge and skills

they need to secure the required quality for our products. And we are providing safety trainings

and safety tools and equipment to aid our operators to do their job well.

-

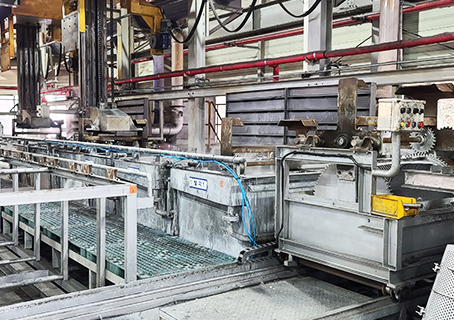

STEP01

Pre-treatment

Production of our parts is processed in three stages. And during the 1st stage, we carry out

pre-treatment for our parts to remove undesired substances and residues on the surface in order to

improve precision and quality in the products through shot blasting, sanding, degreasing,

phosphating, and coating.-

Shot blasting / Sanding

- Incoming materials are shot blasted to get rid of corrosion and undesired substances on the surface. It also secures enough space on the parts for adhesion.

-

Degreasing

- Oil residue on materials is removed.

Phosphating

- Oil residue is removed while preventing corrosion by creating a phosphating film on the surface.

-

Coating

- There are three ways to apply adhesives on the material surface as below : Rolling, Dipping, Spraying.

-

-

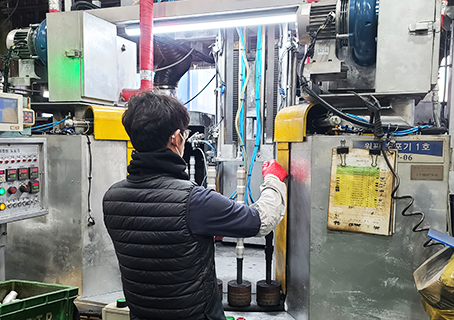

STEP02

Vulcanization

The 2nd stage is process injecting rubber into iron or aluminum metal components. To enhance product quality, DN has introduced a number of automatic machines while providing trainings and upgrading operation environment for our operators.

A.metal part

B.Rubber injection bonding

C.Finished goods

-

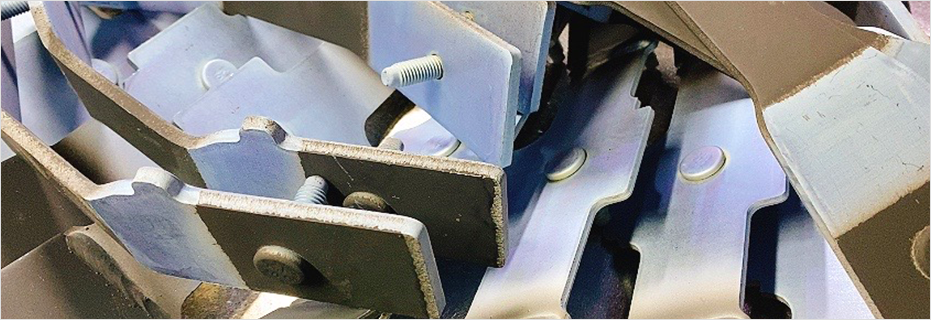

STEP03

Post-process

Finally, the 3rd stage is to make finished goods after additional post-processes such an

anti-corrosion, precision improvement, buffing, and welding as needed. Although quality improvement

activities are carried out in previous stages, It is critical not to miss even small elements in this

stage to produce outstanding products which meet or exceed customer requirements.-

Buffing

Buffing- Vulcanized rubber parts are deburred.

-

Welding

Welding- After vulcanization, the rubber parts are coupled with metal components.

-

A-coating

A-coating- Parts are electro-painted to prevent corrosion.

-

Assembling

Assembling-

Parts are assembled with rest of components.

(Press-in, bolting, riveting, etc.)

-

Parts are assembled with rest of components.

-

Swaging

Swaging-

The outer diameter in bushes is reduced.

(in order to adjust dimensions and remove remaining stress)

-

The outer diameter in bushes is reduced.

-

Inspection

Inspection- Parts are tested to see if characteristics required by customers are satisfied. (on site)

-